How robots are changing the world of high jewellery, from reducing production costs to creating daring new designs – but can AI ever replicate the delicate touch of a human craftsman?

We’re officially in the future, with the jewellery industry the latest to be shaken up by robots that are creating pieces that might not touch a human hand before they are worn for the first time.

While the benefits of automation are significant, including cutting down on production costs and saving time, there are questions as to whether robots can truly replace the human touch needed for the most high-quality pieces.

Vintage jewellery is having a viral moment – thanks to Taylor Swift

Still, as the industry continues to face a shortage in manpower, the use of robotics is likely to become more commonplace, particularly when it comes to producing lower-quality pieces. Studios are investing in automation to broaden their manufacturing capacity.

Conventional manufacturing, including of jewellery, is traditionally a labour-intensive process. This creates big challenges in monitoring and managing production, including variations in product types and processes, manufacturing time and scheduling.

The Hong Kong Institution of Engineers has described industrial digitalisation as an efficient solution for improving productivity and resource management through simulation. Potential benefits include a higher worker utilisation rate, reduced production consumption and more efficient production processes.

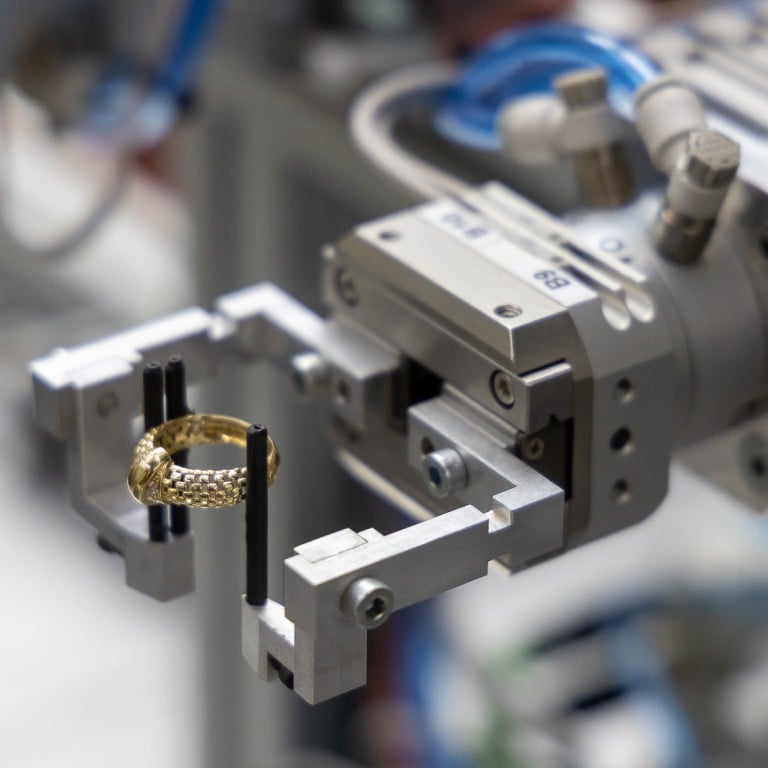

In October 2022, Christian Tse, founder of California-based Christian Tse Designs & Manufacturing, began producing jewellery using a modular robotic system developed by engineering firm Flexible Robotic Environment (FRE).

The system is “the most powerful, flexible and user-friendly jewellery processing system in the world today”, Tse said at the time.

“These new robots will save our clients labour costs, and the automated precision will automatically create a better-finished product for the fine jewellery consumer.

“Robotic polishers allow optimal efficiency and cost savings for the fine jewellery brands we manufacture for.”

From Harry Styles to Pharrell, all these men have worn women’s jewellery with pride

Tse’s robots can polish most rings, earrings, bracelets, pendants and brooches, and require minimal human supervision. The system includes one robot that holds a piece of jewellery and another that holds the specific polishing tool for that particular design.

Using robots can help jewellery manufacturers boost production efficiency by lowering waste, optimising the use of raw materials and better tracking production data.

Another system developed by FRE allows manufacturers to produce an entire shift’s worth of products in a single hour. The system can be deployed for long or short orders, depending on the firm’s needs, and it can automatically adapt to the size and shape variations of different pieces of jewellery.

The industry has been looking to technology and automation to strengthen its operations for some time.

Hong Kong-based jewellery giant Chow Tai Fook has deployed automation in production and inventory replenishment to shorten production lead times. The group has built an automated logistics and distribution centre in mainland China, where a warehousing and surveillance system enabled by the Internet of Things and radio frequency identification provides real-time inventory management and item-level stock movement data.

The potential of robotics for the company and the industry is evident in a recent video shared on the company’s Facebook page in which Chow Tai Fook executive director Adrian Cheng shakes hands with a robot and writes: “Robots fascinate me! At Chow Tai Fook Jewellery, we are pioneers in using deep robotics and automation to improve the efficiency and accuracy of diamond cutting and polishing.

“By 2025, we’ll use smart manufacturing for half our production, increasing our productivity by 30 per cent every year,” he continues. “Smart logistics and smart retail will also help create more innovative and better-quality personalised products and experiences that our customers love.”

The use of robots in the jewellery industry is spreading globally.

In one example, Italian luxury fashion house Bulgari celebrated 75 years of its Serpenti series with a luxurious display in Milan, where an installation by Italian artist Davide Quayola featured a robot arm giving a live chiselling performance. The robot was guided by algorithms and attempted to finish shaping incomplete figures.

High jewellery in 2024: the trends, products and predictions you should know

In another, Dutch retailer My Jewellery teamed up with Geek+, a mobile robotics player, to use automation to deliver jewellery efficiently and sustainably.

While creative industries and technology don’t always go hand in hand, the jewellery industry is gradually adapting to advancements that have already revolutionised other industries. Computer-aided design, augmented reality and 3D printing have already entered the mainstream. Robotics is the logical next step.

Some full-service engineering companies are specialising in automated jewellery processing systems and developing products to process and polish various types of jewellery. Robotic polishing can significantly streamline polishing departments, cutting down on production bottlenecks and increasing production volumes.

Patented hardware and software solutions can create high-quality products at lower prices. However, there are several concerns with the increasing use of robotics in the jewellery industry. While machines can take care of basic casting and model making to a certain quality, a human touch is still required to produce the very best pieces. According to one jewellery industry executive, robots cannot finish products the same way a person can.

Is modular jewellery the future of fashion? 2023’s best detachable pieces

That said, companies are investing in robotics to speed up manufacturing, including focusing on creating mountings with a human doing the final setting. Such partnerships could be a game changer for the industry, making it possible to mass-produce unique pieces faster and more efficiently.

Vietnamese IT services provider FPT Software has joined hands with Danish jewellery brand Julie Sandlau to build a smart jewellery factory in Vietnam. By integrating digital technologies like robotic process automation and artificial intelligence, such factories have the potential to transform the centuries-old jewellery industry forever.

- Italian luxury brand Bulgari celebrated 75 years of its Serpenti series with an installation in Milan by artist Davide Quayola – in which a robot arm gave a live chiselling performance

- ‘Robots fascinate me!’: Hong Kong-based jewellery giant Chow Tai Fook shared a video on its Facebook page in which executive director Adrian Cheng shook hands with a robot